Choke And Kill Manifolds Components

Choke and kill manifold components include swivel joints, integral joints, high-pressure pup joints, and short conversion (adjustable) joints.

All components can be manufactured according to customer specifications

-

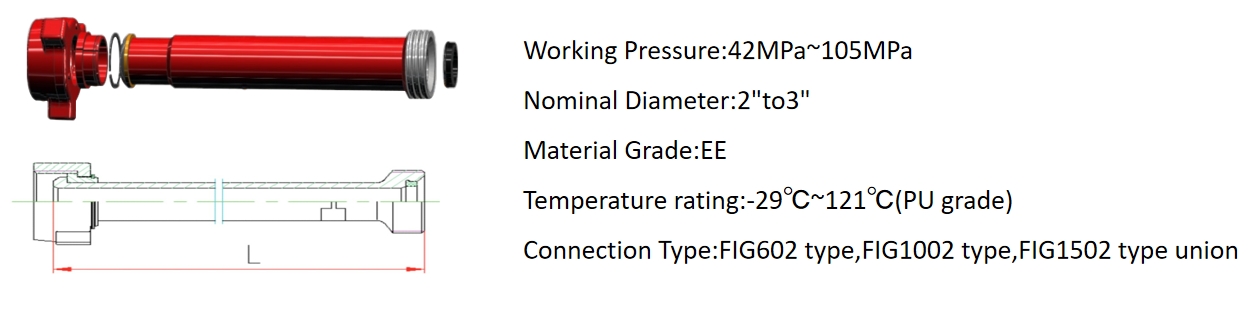

◆ Technical Data

◆ Product Description

High pressure movable elbow is a kind of metal pipeline joint equipped with ball bearings, which is a common tool for connecting pipelines and washing sand in oilfield workover operations. It has the characteristics of variable adjustment orientation, quick connection, reasonable structure, small volume, light weight, good sealing performance, safety and reliability, and easy operation. Its specifications are 2"~4", rated working pressure 42~105MPa (6000psi~15000psi), can provide a variety of models of normal temperature, low temperature and sulfur gas conditions used in the repair kit

◆ Design Features

● Swivel Joints is bent on CNC machine tools, molding, uniform thickness and long service life.visual quality can be comparable with the import of rough

● Synthetic rubber seals with metal ring blowout preventer, while the design of pressure relief hole when the seal leakage is automatically reduced to prevent pressure accumulated in the cavity of the fairway,the use of security is greatly enhanced

● Swivel Joints three fairways designed to more effectively withstand heavy load and radial load,so that when the pressure stable when subjected to changing load, smaller pipeline vibration

● Swivel Joints field service usually requires only occasional lubric-ation can ensure their normal work

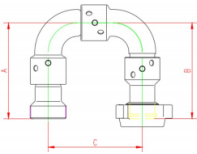

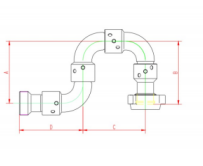

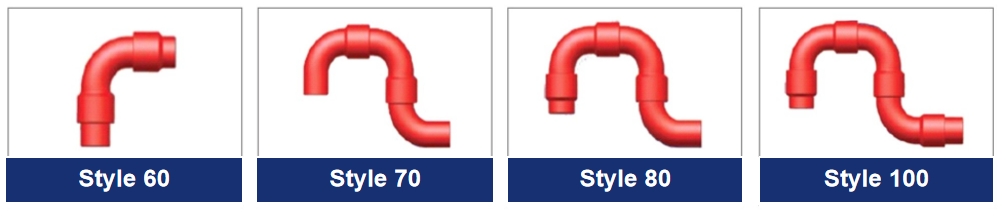

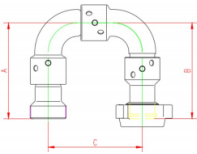

- Long radius bend 10 Swivel Joints

- Long radius bend 50 Swivel Joints

- Long radius bend 80 Swivel Joints

- Long radius bend 100 Swivel Joints

- Active elbow repair kit

-

Product Name

Specification

Working Pressure

Type of Connection

Dimensions

(mm)

Weight

(kg)

Use Conditions

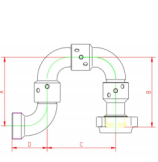

Drawing

A

B

C

Long Radius Bend Swivel Joints

2"

42/6000

FIG602(F×M)

279

277

273

24.5

standard

Type 10 F-M

3"

FIG602(F×M)

368

368

416

55.3

standard

FIG602(M×M)

368

368

416

61.4

standard

4"

FIG602(M×M)

408

408

484

85.8

standard

2"

70/10000

FIG1002(F×M)

279

277

273

27.7

standard

3"

FIG1002(F×M)

368

368

416

58.7

standard

4"

FG1002(F×M)

408

408

484

89.8

standard

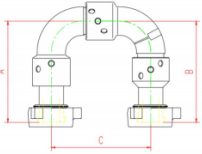

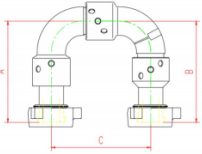

Type 10 M-M

2"

105/15000

FIG1502(F×M)

279

277

273

27.7

standard

FIG1502(M×M)

279

277

273

31.8

standard

3"

FIG1502(M×M)

368

368

416

64.8

standard

FIG1502(F×M)

368

368

416

58.7

standard

4"

FIG1502(F×M)

408

408

484

89.8

standard

-

Product

Name

Specification

Working

Pressure

Type of

Connection

Dimensions

(mm)

Weight

(kg)

Use

Conditions

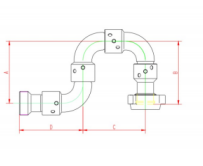

Drawing

A

B

C

Long Radius Bend Swivel Joints

2"

42/6000

FG602(F×M)

140

277

277

23.4

standard

Type 50 F-M

3"

FIG602(F×M)

202

268

416

45.2

standard

4"

FIG602(F×M)

236

406

481

70.2

standard

2"

70/10000

FG1002(F×M)

140

277

277

25.5

standard

3"

FIG1002(F×M)

202

268

416

48.4

standard

4"

FIG1002(F×M)

236

406

481

125

standard

2"

105/15000

FIG1502(F×M)

140

277

277

25.5

standard

2"

FIG1502(M×M)

140

277

277

27.2

standard

3"

FIG1502(M×M)

202

268

416

52.3

standard

3"

FG1502(F×M)

202

268

416

48.4

standard

4"

FIG1502(F×M)

236

406

481

73.3

standard

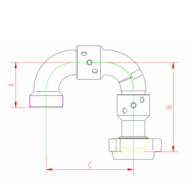

-

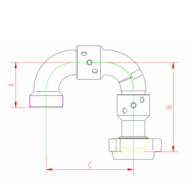

Product

Name

Specification

Working Pressure

Type of

Connection

Dimensions

(mm)

Weight

(kg)

Use

Conditions

Drawing

A

B

C

D

Long Radius Bend Swivel Joints

2"

42/6000

FIG602(F×M)

277

277

273

140

34.2

standard

Type 80 F-M

3"

FG602(F×M)

416

368

416

202

62.1

standard

4"

FIG602(F×M)

406

406

408

236

80.5

standard

2"

70/10000

FIG1002(F×M)

277

277

273

140

36.5

standard

3"

FIG1002(F×M)

416

368

416

202

65.9

standard

4"

FIG1002(F×M)

406

406

408

236

85.3

standard

2"

FIG1502(F×M)

277

277

273

140

36.5

standard

3"

FIG1502(FxF)

416

368

416

202

65.9

standard

4"

FIG1502(F×M)

406

406

408

236

85.3

standard

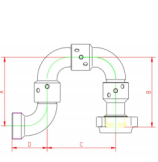

-

Product

Name

Specification

Working Pressure

Type of

Connection

Dimensions

(mm)

Weight

(kg)

Use

Conditions

Drawing

A

B

C

D

Long Radius Bend Swivel Joints

2"

42/6000

FIG602(F×M)

273

277

273

279

33.7

standard

Type 100 F- M

3"

FIG602(F×M)

416

368

416

368

74.3

standard

4"

FIG602(F×M)

408

406

408

327.5

94.8

standard

2"

70/10000

FIG1002(F*M)

273

277

273

279

37.5

standard

3"

FIG1002(F*M)

416

368

416

368

76.1

standard

4"

FIG1002(F*M)

408

406

408

327.5

98.5

standard

2"

105/15000

FIG1502(F*M)

273

277

273

279

37.5

standard

2"

FIG1502(M*M)

273

277

273

279

40.7

standard

3"

FIG1502(M*F)

416

368

416

368

76.1

standard

-

Product

Name

Specification

Working Pressure

Packing

(A only)

O-ring

Steel Ball Stopper

Circlip For Hole

Oil Plug

Steel Ball

Drawing

I

Ⅱ

Ⅲ

Repair Kit

2"

42/6000

1

1

1

3

3

3

3

28

3"

1

1

1

3

3

3

3

38

4"

1

1

1

3

3

3

3

45

2”

70/10000

1

1

1

3

3

3

3

28

3"

1

1

1

3

3

3

3

38

4"

1

1

1

3

3

3

3

45

2"

105/15000

1

1

1

3

3

3

3

28

2"

1

1

1

3

3

3

3

28

3"

1

1

1

3

3

3

3

38

4"

1

1

1

3

3

3

3

45

-

◆ Technical Data

◆ Product Description

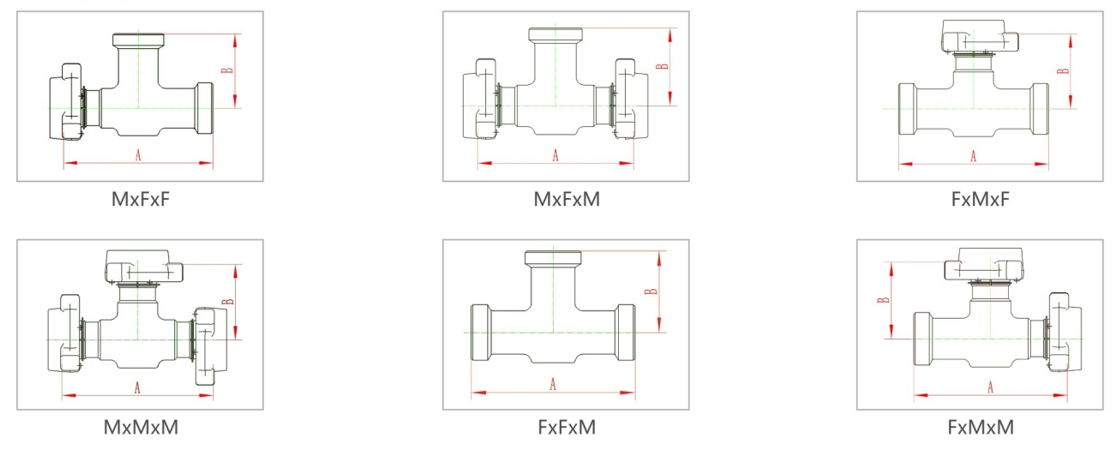

The integral joint is an indispensable part in the connection of high-pressure fluid pipelines, which can effectively realize the functions of fluid diversion, parallel flow, fluid change, etc. The integral joint is a series of products innovated and improved by the company on the basis of digesting and absorbing similar foreign product technology. Its specifications are 2 "~3", rated working pressure 42~105MPa(6000psi~15000psi),it can provide various models and specifications for use under normal temperature, low temperature and sulfur-containing gas conditions. The whole joint variety is complete, the quality is stable, in addition to the types listed below, can be customized according to the user needs for special purposes and specifications of the whole joint.

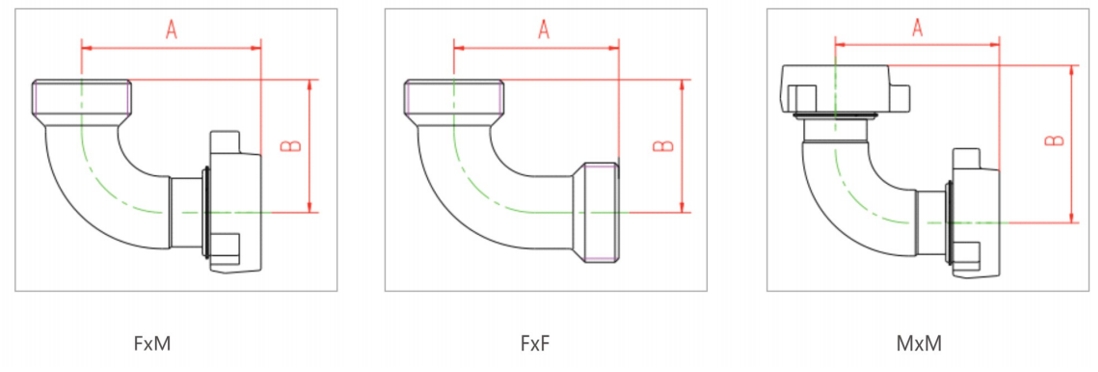

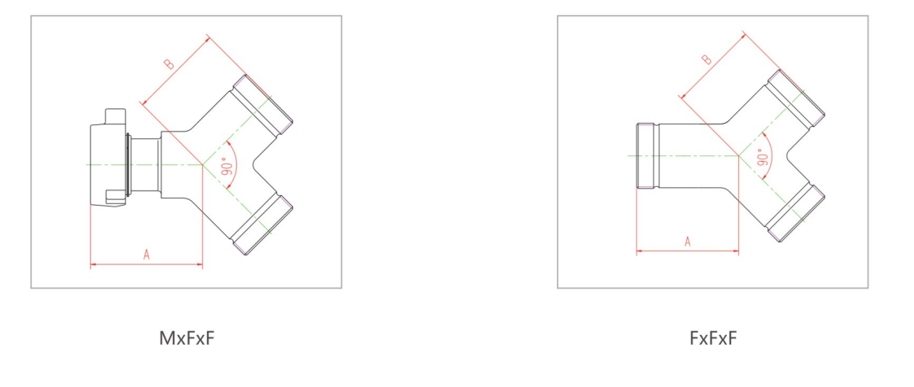

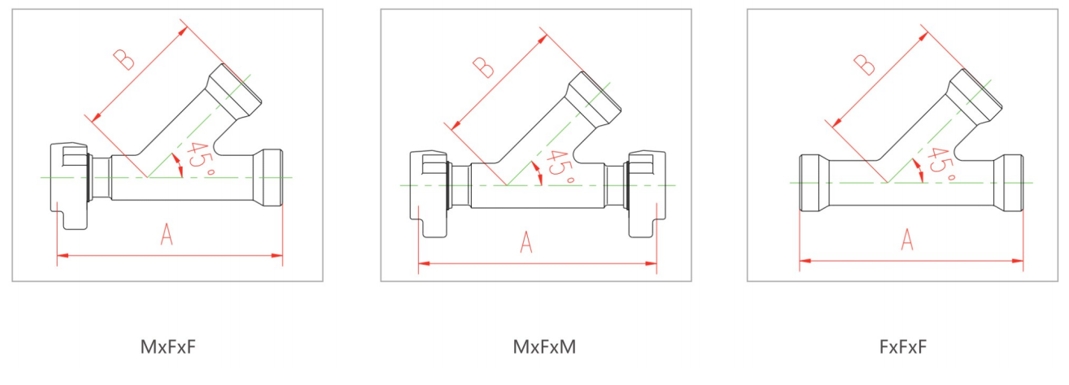

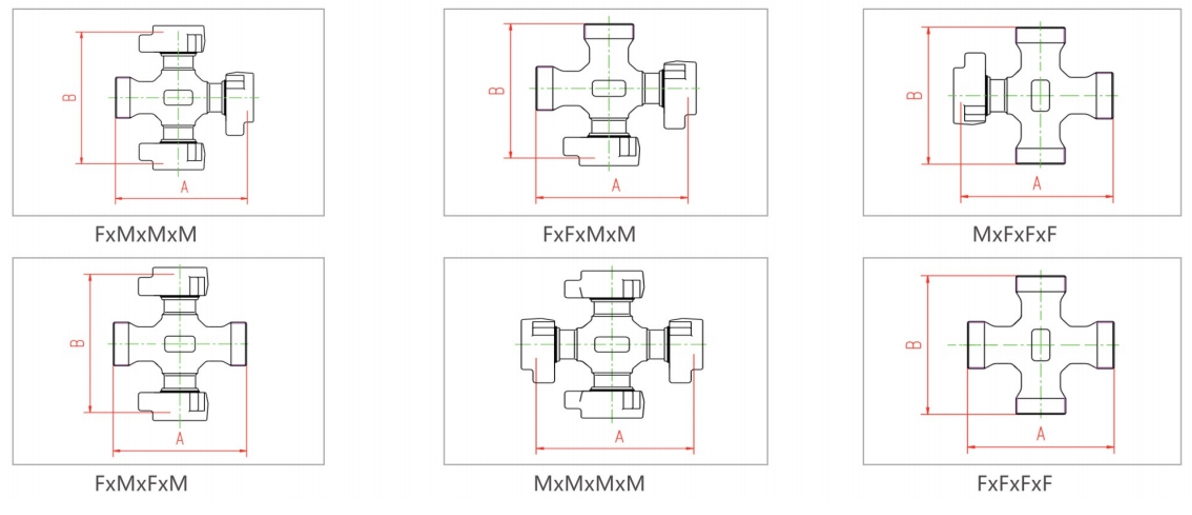

Integral joints (L-shaped 90° elbow, long radius 90° elbow, T-shaped joint, Y-shaped joint, manifold joint, cross joint, etc.)

◆ Design Features

The integral joint is made of high quality alloy steel. After strict heat treatment, it has the characteristics of compact structure, uniform wall thickness, long service life, beautiful appearance, strong interchangeability and convenient connection. In the elbow, joint and other fluid change direction, the inner wall erosion is more serious place designed to do thickening treatment, extend the safe service life

-

Product

NameSpecification

Working

PressureDimensions

(mm)

Type of Connection

Weight

(kg)

Use Conditions

A

B

T-Joint2"

42MPa

308

154

FIG602(M×F×F)

14.2

Standard

308

154

FIG602(M×F×M)

16.3

308

154

FIG602(F×M×F)

14.2

308

154

FIG602(F×F×F)

12

308

154

FIG602(M×M×M)

18.6

308

154

FIG602(F×M×M)

16.3

3"

428

214

FIG602(M×F×F)

56.2

428

214

FIG602(M×F×M)

61.7

428

214

FIG602(F×M×F)

56.2

428

214

FIG602(F×F×F)

50.8

428

214

FIG602(M×M×M)

67.1

428

214

FIG602(F×M×M)

61.7

2"

70MPa

308

154

FIG1002(M×F×F)

17

308

154

FIG1002(M×F×M)

20.9

308

154

FIG1002(F×M×F)

17

308

154

FIG1002(F×F×F)

13.2

308

154

FIG1002(M×M×M)

24.7

3"

428

214

FIG1002(F×M×M)

64.4

428

214

FIG1002(M×F×F)

58

428

214

FIG1002(M×F×M)

64.4

428

214

FIG1002(F×M×F)

58

428

214

FIG1002(F×F×F)

51.7

2"

105MPa

308

154

FIG1502(M×F×F)

17

308

154

FIG1502(M×F×M)

20.9

308

154

FIG1502(F×M×F)

17

308

154

FIG1502(F×F×F)

13.2

308

154

FIG1502(M×M×M)

24.7

3"

428

214

FIG1502(F×M×M)

64.4

428

214

FIG1502(M×F×F)

58

428

214

FIG1502(M×F×M)

64.4

428

214

FIG1502(F×M×F)

58

428

214

FIG1502(F×F×F)

51.7

-

Product

NameSpecification

Working

Pressure

Dimensions(mm)

Type of Connection

Weight

(kg)

Use Conditions

A

B

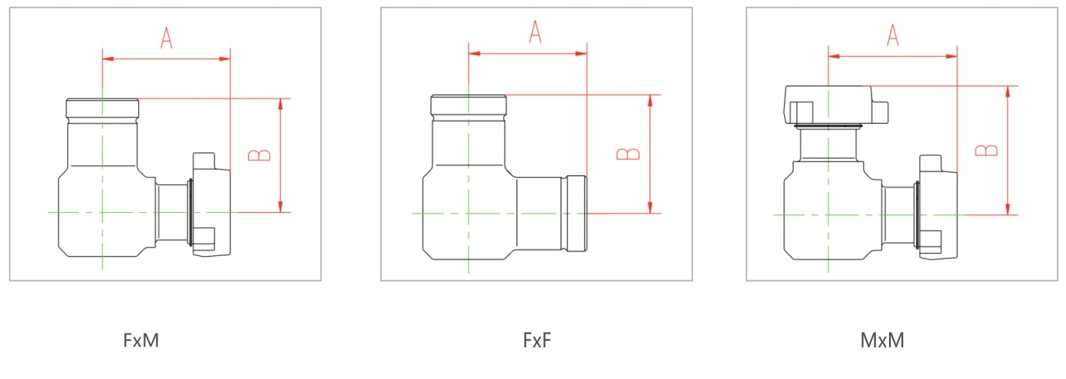

L-90°Elbow2"

42MPa

154

154

FIG602(F×M)

12.4

Standard

154

154

FIG602(F×F)

8.2

154

154

FIG602(M×M)

16.3

3"

214

214

FIG602(F×M)

45.6

214

214

FIG602(F×F)

38.1

214

214

FIG602(M×M)

52.2

2"

70MPa

154

154

FIG1002(F×M)

14.7

154

154

FIG1002(F×F)

10.9

154

154

FIG1002(M×M)

18.5

3”

214

214

FIG1002(F×M)

46.3

214

214

FIG1002(F×F)

39.5

214

214

FIG1002(M×M)

54.9

2"

105MPa

154

154

FIG1502(F×M)

14.7

154

154

FIG1502(F×F)

10.9

154

154

FIG1502(M×M)

18.5

3"

214

214

FIG1502(F×M)

46.3

214

214

FIG1502(F×F)

39.5

214

214

FIG1502(M×M)

54.9

-

Product

Name

Specification

Working

Pressure

Dimensions(mm)

Type of Connection

Weight

(kg)

Use

Conditions

A

B

Long Radius

90 °Elbow2"

42MPa

162

171

FIG602(F×M)

10

Standard

162

171

FIG602(F×F)

7.8

162

171

FIG602(M×M)

12.2

3"

239

202

FIG602(F×M)

24.5

239

202

FIG602(F×F)

19.5

239

202

FIG602(M×M)

29.5

2"

70MPa

162

171

FIG1002(F×M)

12.6

162

171

FIG1002(F×F)

11.8

162

171

FIG1002(M×M)

15.4

3"

239

202

FIG1002(F×M)

22.9

239

202

FIG1002(F×F)

15.8

239

202

FIG1002(M×M)

30

2"

105MPa

162

171

FIG1502(F×M)

12.6

162

171

FIG1502(F×F)

11.8

162

171

FIG1502(M×M)

15.4

3"

239

202

FIG1502(F×M)

22.9

239

202

FIG1502(F×F)

15.8

239

202

FIG1502(M×M)

30

-

Product

NameSpecification

Working

Pressure

Dimensions(mm)

Type of ConnectionWeight

(kg)

Use ConditionsA

B

Y-Type Joint

2"

42MPa

133

127

FIG602(M×F×F)

12.2

Standard

133

127

FIG602(F×F×F)

10

3"

197

190

FIG602(M×F×F)

33.5

197

190

FIG602(F×F×F)

28.5

2"

70MPa

133

127

FIG1002(M×F×F)

12.7

133

127

FIG1002(F×F×F)

10.5

3"

197

190

FIG1002(M×F×F)

35.2

197

190

FIG1002(F×F×F)

30.5

2"

105MPa

133

127

FIG1502(M×F×F)

12.7

133

127

FIG1502(F×F×F)

10.5

3"

197

190

FIG1502(M×F×F)

35.2

197

190

FIG1502(F×F×F)

30.5

-

Product

NameSpecification

Working

PressureDimensions

(mm)

Type of Connection

Weight

(kg)

Use

Conditions

A

B

Manifold Joint

2"

42MPa

400

250

FIG602(M×F×F)

21.5

Standard

400

250

FIG602(M×F×M)

23.7

400

250

FIG602(F×F×F)

19.3

3"

533

355

FIG602(M×F×F)

40.1

533

355

FIG602(M×F×M)

45.1

533

355

FIG602(F×F×F)

35.1

2"

70MPa

400

250

FG1002(M×F×F)

24.5

400

250

FIG1002(M×F×M)

26.7

400

250

FIG1002(F×F×F)

22.3

3"

533

355

FIG1002(M×F×F)

43.1

533

355

FIG1002(M×F×M)

48.1

533

355

FIG1002(F×F×F)

38.1

2"

105MPa

400

250

FIG1002(M×F×F)

24.5

400

250

FIG1002(M×F×M)

26.7

400

250

FIG1002(F×F×F)

22.3

3"

533

355

FIG1002(M×F×F)

43.1

533

355

FIG1002(M×F×M)

48.1

533

355

FIG1002(F×F×F)

38.1

-

Product

NameSpecification

Working

PressureDimensions

(mm)

Type of Connection

Weight

(kg)

Use Conditions

A

B

Crosses Joint

2"

42MPa

308

308

FIG602(F×M×M×M)

32.7

Standard

308

308

FIG602(F×F×M×M)

30.4

308

308

FIG602(M×F×F×F)

28.1

308

308

FIG602(F×M×F×M)

30.4

308

308

FIG602(M×M×M×M)

35

308

308

FIG602(F×F×F×F)

26.3

3"

428

428

FIG602(F×M×M×M)

87.1

428

428

FIG602(F×F×M×M)

81.6

428

428

FIG602(M×F×F×F)

76.2

428

428

FIG602(F×M×F×M)

81.6

2"

70MPa

308

308

FIG1002(F×M×M×M)

36.3

308

308

FIG1002(F×F×M×M)

33.1

308

308

FIG1002(M×F×F×F)

30

308

308

FIG1002(F×M×F×M)

33.1

308

308

FIG1002(M×M×M×M)

39.5

3"

428

428

FIG1002(F×M×M×M)

89.4

428

428

FIG1002(F×F×M×M)

83

428

428

FIG1002(M×F×F×F)

80.7

428

428

FIG1002(F×M×F×M)

83

2"

105MPa

308

308

FIG1502(F×M×M×M)

36.3

308

308

FIG1502(F×F×M×M)

33.1

308

308

FIG1502(M×F×F×F)

30

308

308

FIG1502(F×M×F×M)

33.1

308

308

FIG1502(F×F×F×F)

26.8

3"

428

428

FIG1502(F×M×M×M)

89.4

428

428

FIG1502(F×F×M×M)

83

428

428

FIG1502(M×F×F×F)

80.7

428

428

FIG1502(F×M×F×M)

83

-

-

◆ Product Description Description

Pup joint is an element cementingand fracturing equipment delivery high-pressure fluid.Widely usedin the acidic operating environment.in the high-pressure discharge line,input line,a temporary flow lines,well testing,and other high-voltage transmission line on the line.Overall pipeline specifications are 2in~3 in,length 0.5 m,1 m,1.5 m,2m,2.5m,3m,3.5m and so on,rated working pressure of 42MPa 105MPa,working temperature -29 ℃~121℃.We can Produce reduction according to customer requirement.Pup joint is an element cementing and fracturing equipment delivery high-pressure fluid. Widely used in the acidic operating environment.in the high-pressure discharge line,input line,a temporary flow lines,well testing,and other high-voltage transmission line on the line.Overall pipeline specifications are 2in~3 in,length 0.5 m,1 m,1.5 m,2m,2.5m,3m,3.5m and so on,rated working pressure of 42MPa~105MPa,working temperature -29℃~121℃.We can Produce reduction according to customer requirement.

◆ Design Features

● Pup jointend on the grounds azelaic without screwing, more secure and reliable

● Loading and unloading easy, fast

● High strength, lightweight

● Various technical parameters and performance meetthe specifications of API Spec 16C, interchangeable with similar foreign products

◆ Technical Data

Product Name

Specification

Working Pressure

Length

( mm )

Type of ConnectionWeight

(kg)

Use

Conditions

L

2"

3"

High-

Pressure Pup Joint2"

3"42MPa

500

FIG602(F×M)

FIG602(F×F)

FIG602(M×M)8.8

18.7

Standard

1000

15

32.4

1500

21.4

46.1

2000

27.8

59.8

2500

34.2

73.5

3000

40.6

87.2

4000

53.4

114.6

5000

66.2

142

6000

79

170

2"

3"70MPa

500

FIG1002(F×M)

FIG1002(F×F)

FIG1002(M×M)8.8

18.7

1000

15

32.4

1500

21.4

46.1

2000

27.8

59.8

2500

34.2

73.5

3000

40.6

87.2

4000

53.4

114.6

5000

66.2

142

6000

79

170

2"

3"105MPa

500

FIG1502(F×M)

FIG1502(F×F)

FIG1502(M×M)8.8

18.7

1000

15

32.4

1500

21.4

46.1

2000

27.8

59.8

2500

34.2

73.5

3000

40.6

87.2

4000

53.4

114.6

5000

66.2

142

6000

79

170

-

◆ Product Description

Adjustable joints at both ends is a different size,buckle-type fittings,tubing connections are essential parts can be manufactured according to user needs.Its specifications are 2"to 4",has rated working pressure 42MPa (6000PSI)and 70MPa(15000PSI),an interface in the form of a variety of types including domestic thread,union class.Available at room temperature,low temperature and sour gas conditions.

◆ Design Features

Our factory plant a variety of end connections form, size of adjustable joints, adjustable joints standard total length of 200mm. Users can according to their needs,the following lit of optional end connection in the form of arbitrary combination and non-standard length.Rated working pressure reducers by connecting the end fitting in the form of lower pressure rating value is determined

◆ Technical Data

No.

End Connections

Rated Working Pressure

Standard Conditions

H₂S Conditions

1

2"FIG602F

42MPa

42MPa

2

2"FIG602M

42MPa

42MPa

3

2"FIG1502F

105MPa

70MPa

4

2"FIG1502M

105MPa

70MPa

5

3"FIG602F

42MPa

42MPa

6

3"FIG602M

42MPa

42MPa

7

3"FIG1502F

105MPa

70MPa

8

3"FIG1502M

105MPa

70MPa

9

4"FIG602F

42MPa

42MPa

10

4"FIG602M

42MPa

42MPa

11

4"FIG1502F

105MPa

70MPa

12

4"FIG1502M

105MPa

70MPa

NOTE:Thread contained pipe threaded,can be customized according to customer demand

OUR PRODUCTS

Anhui MK Petroleum Precision Manufacturing Co. , Ltd.

MKmfg main products: flange,choke manifolds, kill manifolds,hose loop,swivel joints, integral joints, high-pressure pup joints and short conversion (adjustable) joint ... etc.

If you are interested in any of our products, please feel free to contact us.

QUICK ACCESS

OUR COMPANY